2D laser cutting wood

Laser cutting of wood and wood-like materials

For several years, we have been processing a variety of woods and wood-like materials by means of 2D laser cutting systems. Regardless of a material’s inhomogeneous composition and humidity, we aim for the optimal result.

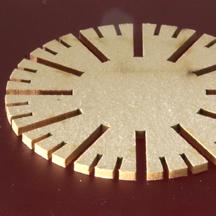

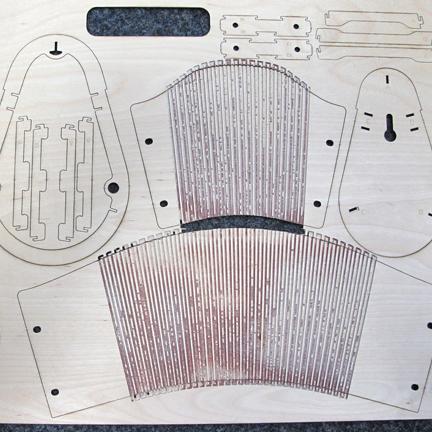

Benefit from our state-of-the-art laser cutting technology. The narrow laser cut offers all the creative freedom you need, as the wooden edges don’t splinter off. That allows more precise and detailed cuts than machined processes do.

The laser’s heat exposure discolors the cutting edges light brown to sooty black, depending on the material.

Benefit from our state-of-the-art laser cutting technology. The narrow laser cut offers all the creative freedom you need, as the wooden edges don’t splinter off. That allows more precise and detailed cuts than machined processes do.

The laser’s heat exposure discolors the cutting edges light brown to sooty black, depending on the material.

However, through skillful choice of parameters and inert gases (nitrogen, argon, and helium), we are able to minimize soot formation. The drier the wood the better the processing results of our CO2 laser cutting systems. Particularly dry wood and plywood like poplar wood, medium-density fiberboards (MDF), paper, and oriented strand boards (OSB) are suitable, as these show almost no edge discoloration after the cutting process.

Should you have any questions regarding 2D laser cutting of wood and wood-like materials, our engineers are happy to advise you. Get in touch with the KURIOS team.

Should you have any questions regarding 2D laser cutting of wood and wood-like materials, our engineers are happy to advise you. Get in touch with the KURIOS team.

Laser cutting wood – beneficial across industries

The detailed and filigree cut edges have proven to be especially useful in trade fair construction, shopfitting, wooden displays and signets as well as in the manufacture of musical instruments.

Wooden inlays with plug-in letters

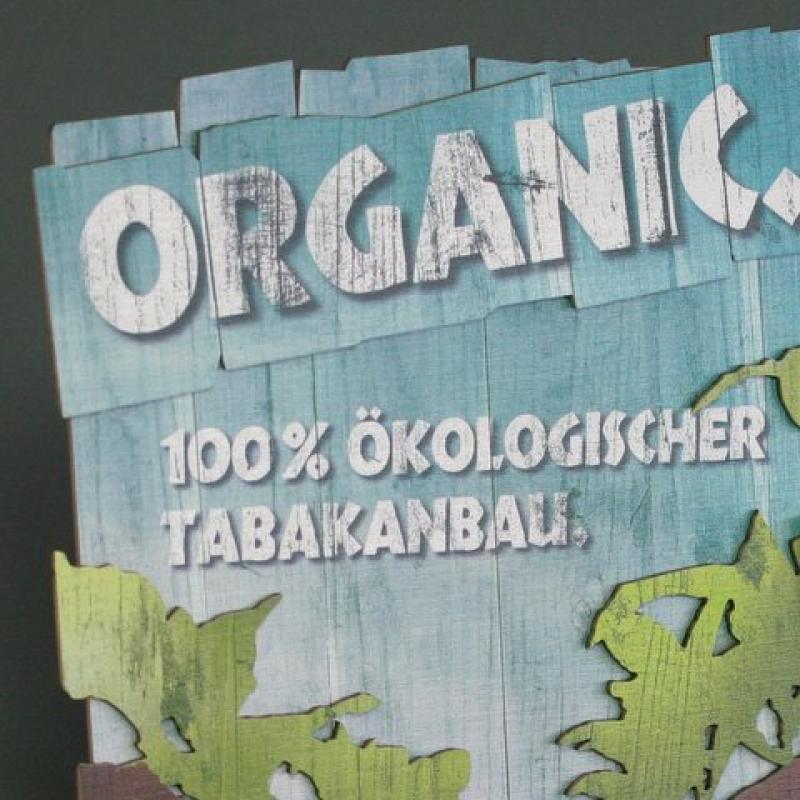

Digital printing on lasered plywood

Technical details for laser cutting wood

For the manufacture of complete products, we offer many options for further processing – all from a single source. We gladly glue, grind, lacquer, mill, and laser mark your woodcuttings according to your wishes. Direct digital printing on plywood is part of our range of services, too.

-

Maximum size:

2,000 mm x 3,000 mm

-

Hardest material:

Oak

-

Softest material:

Poplar

-

Wood-like materials:

Medium-density fiber-boards (MDF) and oriented strand boards (OSB)

-

Further processing offer:

Milling, lacquering, laser marking, drilling, thread cutting, gluing, grinding, and adhesive bonding