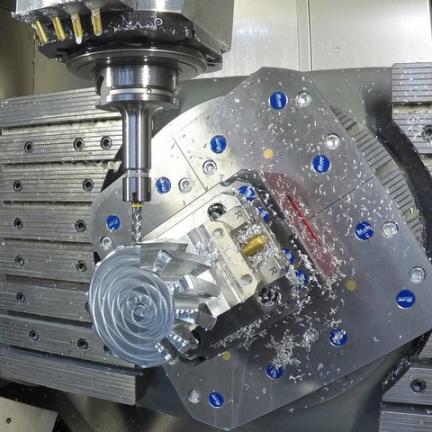

5-axis milling titanium

An outstanding material demands high-performance manufacturing

Titanium is a light metal although it is 70% heavier than aluminium and only about 40% lighter than steel. However, the tensile strength of titanium (300-1,150 N/mm²) is much higher than that of aluminium (250-500 N/mm²) and almost reaches the values of steel (350-1,500 N/mm²).

Titanium is antimagnetic, which makes it completely insensitive to eddy current influences. Therefore, the material is excellently suited in the field of EMC shielding when other materials would not provide sufficient attenuation or would heat up unacceptably.

Titanium immediately forms an oxide layer when exposed to air, which protects the material from further oxidation. This layer is particularly hard and strongly adhesive - this explains the extremely high oxidation resistance to seawater, acids and alkalis.

Titanium is antimagnetic, which makes it completely insensitive to eddy current influences. Therefore, the material is excellently suited in the field of EMC shielding when other materials would not provide sufficient attenuation or would heat up unacceptably.

Titanium immediately forms an oxide layer when exposed to air, which protects the material from further oxidation. This layer is particularly hard and strongly adhesive - this explains the extremely high oxidation resistance to seawater, acids and alkalis.

Titanium and titanium alloys can be machined in a similar way to austenitic steels.machined. Machining by means of the various cutting processes does not pose any fundamentaldifficulties if it is taken into account that the machining

• the tool cutting edge is subjected to high thermal stress due to the relatively low specific heat,titanium's relatively low specific heat, thermal conductivity and density,

• titanium yields to the pressure of the cutting tool due to its low modulus of elasticity and high toughness properties, and

• titanium tends to weld to the tool due to the heat generated at the interface.with the tool due to the heat generated at the interface.

Titanium must therefore be machined at a low cutting speed, with a relatively large and uniform feed rate.feed with an ample supply of coolant using a sharp tool that is clamped as free ofThe tool is clamped in a vibration-free manner and is sharp.

• the tool cutting edge is subjected to high thermal stress due to the relatively low specific heat,titanium's relatively low specific heat, thermal conductivity and density,

• titanium yields to the pressure of the cutting tool due to its low modulus of elasticity and high toughness properties, and

• titanium tends to weld to the tool due to the heat generated at the interface.with the tool due to the heat generated at the interface.

Titanium must therefore be machined at a low cutting speed, with a relatively large and uniform feed rate.feed with an ample supply of coolant using a sharp tool that is clamped as free ofThe tool is clamped in a vibration-free manner and is sharp.

Exemplary applications for titanium

Text

Aluminium mold core for vulcanizing tool

Shaft for a dry ice crusher

5-axis simultaneous milling – important details at a glance

The process chain stands: perfect machine tool technology, zero point clamping systems, tool measurement, workpiece measurement, high-quality machining tools, 3D software solution with fully integrated CAD/CAM coupling, connection to ERP system with complete QA documentation. Quality assurance measures from self-tests to dual controls to SPC methods – adapted QA actions on a high level.

-

Maximum size:

850 mm x 700 mm x 500 mm

-

Minimum material thickness:

0.05 mm

-

Machine:

Hermle C400

-

Further processing offer:

2D and 3D laser cutting, laser welding, laser marking, hydraulic bending, and turning

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, and further galvanic procedures