Thermal Bending with linear heating rods

Thermoplastics are perfectly suitable for bending

Cold forming is an option for some thermoplastics (see hydraulic bending) but most plastics need to be warm. The bending area of the respective plastic has to be heated until the softening temperature is reached, so that it can solidify in its desired shape in a fixture device. It remains difficult to automate these operations, which is why a great deal of experience in terms of heating process, material, and fixture construction is required.

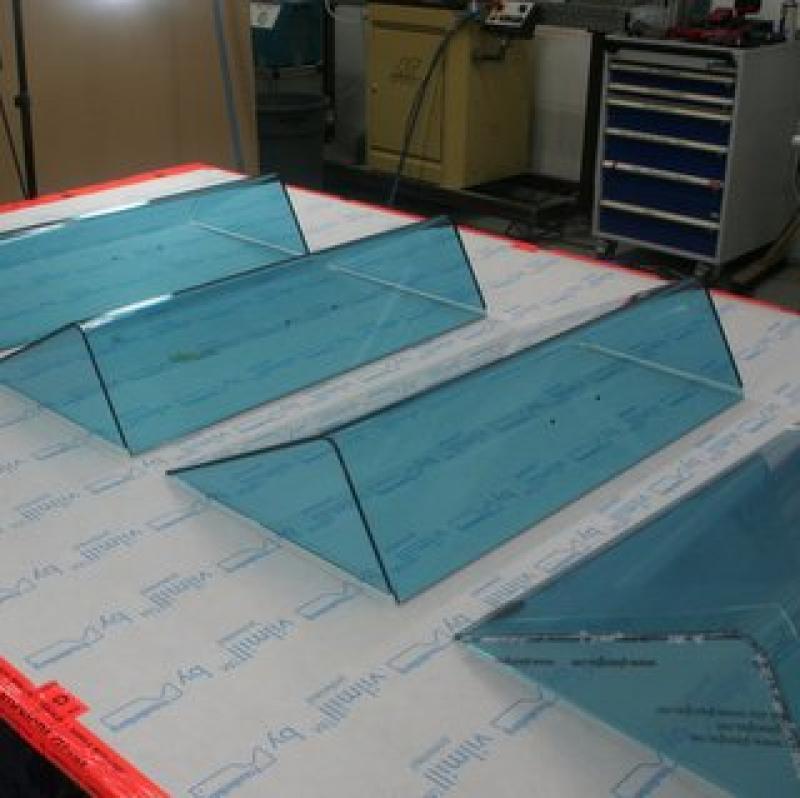

We own various thermal leaf brakes to ensure that we have a suitable system for your demands. Regardless of whether you need us to handle very thin (< 0.5 mm) or very thick (20 mm) plastics, small components or workpieces of up to 3,000 mm width. Here, we make use of different heaters, such as constantan heating wires, glass or ceramics radiators.

We own various thermal leaf brakes to ensure that we have a suitable system for your demands. Regardless of whether you need us to handle very thin (< 0.5 mm) or very thick (20 mm) plastics, small components or workpieces of up to 3,000 mm width. Here, we make use of different heaters, such as constantan heating wires, glass or ceramics radiators.

We find a solution to any thermal bending matter. Our wide-ranging production offers many different opportunities, which encourages lateral thinking and new solutions.

Fixture construction with flexible welding tables has proven to be very effective. It enables us to easily reproduce clamping fixtures. Also, these extremely plane, metallic, perforated tables stabilize and speed up the cooling process.

If you want to be able to unconditionally rely on your service provider at all times, you should get in touch with us. At KURIOS, you will get the perfect solution – guaranteed.

Fixture construction with flexible welding tables has proven to be very effective. It enables us to easily reproduce clamping fixtures. Also, these extremely plane, metallic, perforated tables stabilize and speed up the cooling process.

If you want to be able to unconditionally rely on your service provider at all times, you should get in touch with us. At KURIOS, you will get the perfect solution – guaranteed.

Bent components made of thermoplastic synthetics

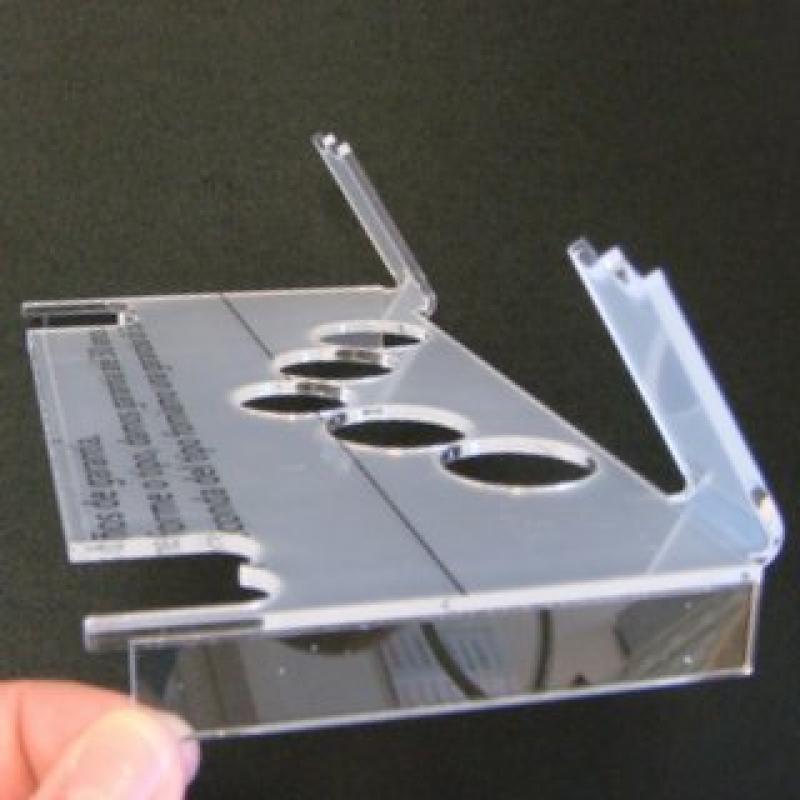

Often, milled or laser-cut components of acrylic glass, PC, or PETG are further processed. Thermal bending is frequently used for products in display construction, shopfitting, and trade fair construction as well as for machine hoods.

Acrylic glass, xt clear, bent for cosmetic display

Bent acrylic hood and pasted sides

Some important facts about bending of thermoplastics

Thermal bending is also suitable for painted, screen-printed, or directly printed products. Here, close cooperation with the respective printing company is necessary in order to take thermostability and distortion of the product into account. All blank materials are processed with protective foil, so that every component is completely undamaged until its final utilization.

-

Bending width:

3,000 mm

-

Material thickness:

from 0.5 mm to 20 mm

-

Design:

SolidWorks or Optiscout

-

Plastic:

Acrylic glass, PC, PETG, APET, POM, PE, ABS, PVC, and others

-

Preparatory work before bending:

2D laser cutting, HSC milling, lacquering, screen printing, direct digital printing

-

Further preparatory work:

3D laser cutting, 3D milling, laser marking, bonding, thread cutting, finishing