CNC Turning – unlimited flexibility

CNC turning in Seevetal near Hamburg – everything from a single source

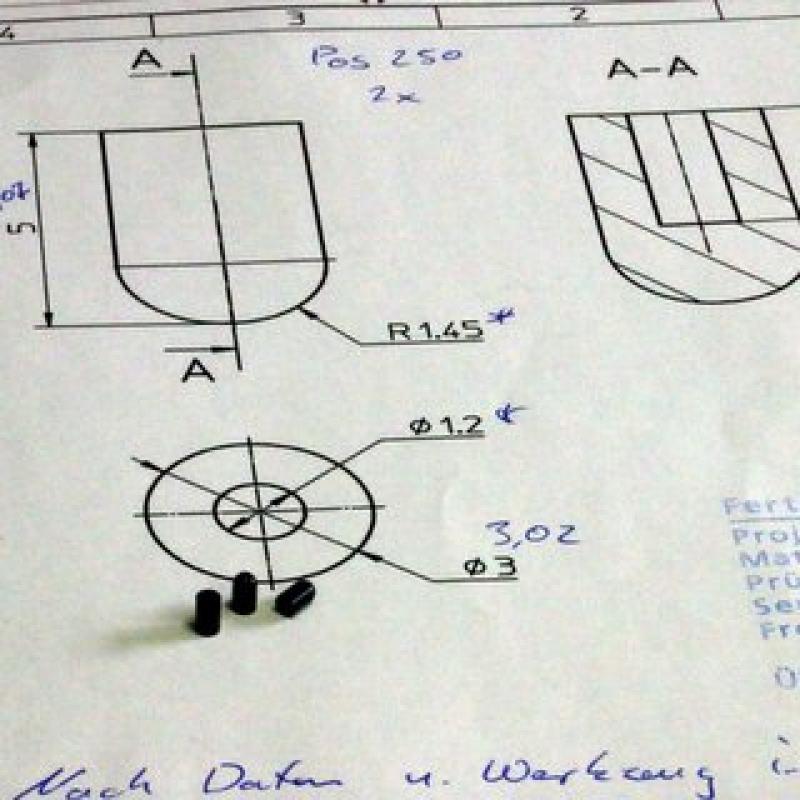

Due to the turret, exchanging various different tools is only a matter of seconds and that way even driven tools can be used directly at the material. Optional preparatory works on the material for our HSC milling machines complete our production portfolio.

We process engineering plastics and high-performance plastics in particular as well as various steel, premium steel, and aluminium alloys. Many years of experience regarding machined separation processes enable us to adjust parameters and tools perfectly to any material and its respective properties.

In addition to alternative cutting methods, various surface refinements are available. You may find a detailed list at the very bottom of this page.

At KURIOS Laserprodukt GmbH precise and smooth operations are guaranteed throughout the entire process chain, from consultancy to your CNC turned components. In order to achieve optimal results, we check every processed part by means of latest in-house FARO metrology, coordinate measuring machines, or electronic measuring equipment.

So, if you want to be able to fully count on your service provider at all times and feel that you are in good hands, you have come to the right place. We would be more than happy to receive your contact.

Possible fields of application for CNC turning

Besides plastics like PA6 (polyamide 6) and POM (polyoxymethylene), we also handle all customary steel, premium steel, and aluminium alloys.

CNC turning – technical data at a glance

-

Diameter:

350 mm x 600 mm

-

Materials:

Engineering plastics, high-performance plastics, light metals (aluminium), premium steel

-

Industries:

Packaging industry, mechanical engineering, food industry, technical semi-finished products

-

Further processing offer:

Laser cutting, laser welding, laser marking, HSC milling, 5-axis simultaneous milling, thermal bending, and hydraulic bending

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, barrel finishing, powder coating, and further galvanic procedures