Laser Marking in Seevetal near Hamburg

Laser marking and laser engraving – clearly identifiable at all times

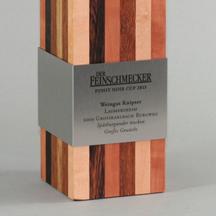

Natural materials (wood, MDF, veneer, cardboard, etc.)

Plastics (acrylic glass, ABS, PA foam, etc.)

Metal (steel, premium steel, aluminium, brass, etc.)

CO2 and Nd:YAG lasers mark by

Foaming – a contrasty, porous surface occurs – or

Removing – eliminating material changes the contrast – or

Carbonizing – “burning” material results in a high contrast

Customer data is often fed into our CAD/CAM system and further processed. We have got the respective import filters for almost all external data formats.

We are looking forward to your request regarding laser marking. Please contact us.

Exemplary fields of application – unlimited flexibility

Laser engraving of material – the key facts summarized

-

Maximum size of flat material:

2,000 mm x 3,000 mm

-

Minimum material thickness:

non-rigid material from 0.05 mm

-

Maximum size of workpiece:

1,000 mm x 500 mm x 500 mm

-

Further processing offer:

Laser cutting, milling engravings, thread cutting, drilling, turning, milling, and Heli-Coil

-

Surface refinements:

Lacquering, high-gloss polishing, sandblasting, abrasive blasting, grinding, brushing, and further galvanic procedures

-

Possible applications:

Display construction, signets, trophies, awards, giveaways, tempered engravings

-

Possible materials:

Wood, natural materials, plastics (Plexiglas®, Perspex®, and others), aluminium, brass, steel sheet, iron, etc.