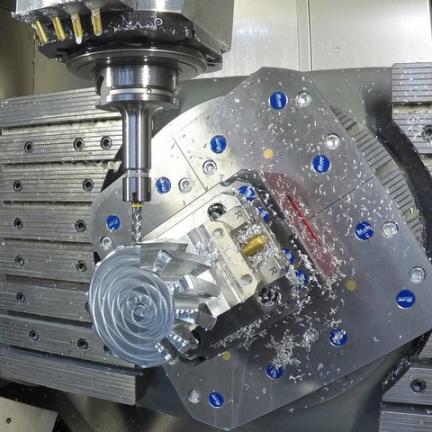

5-axis milling non-ferrous metal

Design elements or technical components made of non-ferrous metals

Non-ferrous metals are commonly referred to as cadmium (Cd), cobalt (Co), copper (Cu), nickel (Ni), lead (Pb), tin (Sn) and zinc (Zn), but also the alloys brass, bronze or gunmetal.

These non-ferrous metals captivate with their colourful hues and are therefore often used as decorative metal elements in addition to technical applications where their metallurgical aspects are decisive.

These non-ferrous metals captivate with their colourful hues and are therefore often used as decorative metal elements in addition to technical applications where their metallurgical aspects are decisive.

Bearings or sliding elements have been used in mechanical engineering for decades - the tribological properties of alloys containing tin, lead or similar soft materials have been known and tested for a long time.

When machining these materials, these lubricating properties often become a challenge during machining - but the selection of suitable tools and machining strategies usually leads to success.

When machining these materials, these lubricating properties often become a challenge during machining - but the selection of suitable tools and machining strategies usually leads to success.

Exemplary applications for the Non-Ferrous Metal material

Gunmetal or machine bronze is often used for components in mechanical engineering because of its good castability. The two alloys RG5 (CuSn7Zn4Pb7) and RG7 (CuSn5Zn5Pb5) are frequently used here. Their origin lies in cannon construction as "gun metal", but due to its excellent emergency running properties it very quickly became established in pump and locomotive construction. Brass alloys, also known as brass castings, are used in a wide variety of everyday objects, but also in technical applications where tribological properties, good thermal conductivity or electrical conductivity are required.

Due to the visually appealing colouring of the non-ferrous metals, they are often used in the decorative sector, and the easy formability and machinability are also useful here.

Due to the visually appealing colouring of the non-ferrous metals, they are often used in the decorative sector, and the easy formability and machinability are also useful here.

Aluminium mold core for vulcanizing tool

Shaft for a dry ice crusher

5-axis simultaneous milling – important details at a glance

The process chain stands: perfect machine tool technology, zero point clamping systems, tool measurement, workpiece measurement, high-quality machining tools, 3D software solution with fully integrated CAD/CAM coupling, connection to ERP system with complete QA documentation. Quality assurance measures from self-tests to dual controls to SPC methods – adapted QA actions on a high level.

-

Maximum size:

850 mm x 700 mm x 500 mm

-

Minimum material thickness:

0.05 mm

-

Machine:

Hermle C400

-

Further processing offer:

2D and 3D laser cutting, laser welding, laser marking, hydraulic bending, and turning

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, and further galvanic procedures