HSC Milling – unlimited flexibility

HSC milling in Seevetal near Hamburg – everything from a single source

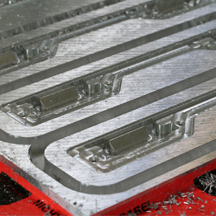

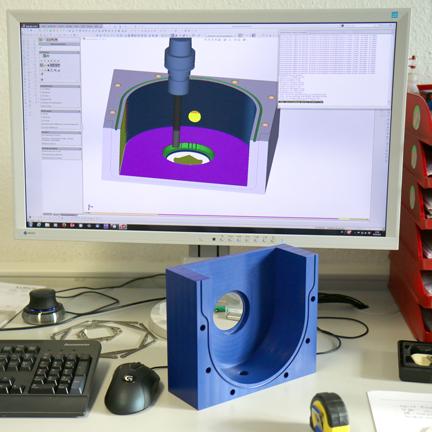

By using HSC spindles with speed of up to 60,000 rpm, we are able to work reliably in each material’s optimal process window. Cutting speed and feed rate are tuned perfectly, so that best cutting quality and surface quality can be assured.

We process a great many light metals, composites, natural materials, and virtually all plastics on our HSC milling systems. The machine’s editing area extends as far as 2 m x 3 m and up to material thicknesses of 100 mm. Latest vacuum clamping technology enables us to securely hold and process even non-rigid or slightly corrugated materials.

We are looking forward to your request regarding HSC milling (2.5D milling). Please feel free to get in touch with us.

Possible fields of application – HSC milling of material

2D-2.5D milling – the key facts

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum material thickness:

non-rigid material from 0.05 mm

-

Maximum material thickness:

100 mm

- Natural material, wood, MDF, HDF, OSB, advertising plastics, engineering plastics, high-performance plastics, aluminium, aluminium composites, multi-wall sheets

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, and further galvanic procedures

-

Industries:

Trade fair construction, model construction, shopfitting, automotive, aviation, precision tools for the medical sector

-

Further processing offer:

Laser marking, engraving, thread cutting, drilling, turning, thermal bending, laser cutting, milling grooves, bending, milling v-grooves, and Heli-Coil