2D Laser Cutting MDF (Wood)

Laser cutting of medium-density fiberboards (MDF)

Medium-density fiberboards consist of defibrated, mostly bark-free softwood. These fibers are gently pressed together, so that a homogeneous material is formed. This material is less “stubborn” than natural wood while being just as strong.

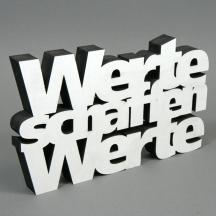

Due to the wood-like material’s even structure, it is perfect for CO2 laser cutting. The structure of the material remains largely unaffected by temperature and humidity. In contrast to HSC milling, when laser cutting MDFs no processing radii occur, so even filigree and sharp-edged contours are feasible.

Due to the wood-like material’s even structure, it is perfect for CO2 laser cutting. The structure of the material remains largely unaffected by temperature and humidity. In contrast to HSC milling, when laser cutting MDFs no processing radii occur, so even filigree and sharp-edged contours are feasible.

During the cutting process, light brown to almost black cutting edges come about, depending on the material’s thickness. This effect is often used as an intentional design element.

Gluing, grinding, lacquering, marking, or milling of your MDF cuttings are further services we can provide upon request as well as direct digital printing.

For questions regarding 2D laser cutting of wood and wood-like materials, the KURIOS team is there to assist you with consultation. Please contact us.

Gluing, grinding, lacquering, marking, or milling of your MDF cuttings are further services we can provide upon request as well as direct digital printing.

For questions regarding 2D laser cutting of wood and wood-like materials, the KURIOS team is there to assist you with consultation. Please contact us.

Ambitious results for ambitious customers

Medium-density fiberboards are popular among the industries of furniture manufacturing, model construction, trade fair construction, shopfitting, as well as in advertisements and façade construction, especially if you are looking for a reasonably priced base material.

Laser cutting of 10 mm cork

Laser cutting of maple

Technical details for laser cutting MDF

The fiberboard entered the European market in the late 1980s and has become an integral part in the industry as well as at KURIOS. Medium-density fiberboards are not only available in natural finish but also in colors like black, red, and blue. HPL coated MDFs are perfectly laser processable, too.

Laser cutting of medium-density fiberboards is very cost-efficient, no matter whether you are looking for individual items, small batches, or large-scale production.

-

Maximum size:

2,000 mm x 3,000 mm

-

Thinnest material:

Veneer thickness

-

Softest material:

20 mm

-

Exemplary areas of application:

Display building, furniture manufacturing, model construction, advertisements, Christmas tree decorations, arts and crafts, façade construction, shop equipment, and trade fair construction

-

Further processing offer:

Milling, lacquering, laser marking, drilling, thread cutting, gluing, grinding, digital printing, and adhesive bonding