2D Laser Cutting Acrylic Glass

Laser cutting of acrylic – for more than 20 years

Ever since its development, acrylic glass (PMMA – polymethyl methacrylate) is enjoying ever-growing popularity. Countless industries have come to appreciate its positive characteristics. Acrylic glass is highly shatterproof, robust, temperature-resistant, weather-resistant, aging-resistant, easy to maintain, easy to process, and is permitted to be used in the food processing industry.

Laser cutting of acrylic glass (PMMA) has been one of our core competencies for more than 20 years. Our machinery includes seven modern, high-precision CO2 laser cutting systems, which run particularly smooth. These systems cut smallest and finest structures without any problems, as well as material thicknesses of up to 40 mm. The edges are being polished at the same time, which makes subsequent reworking redundant.

Laser cutting of acrylic glass (PMMA) has been one of our core competencies for more than 20 years. Our machinery includes seven modern, high-precision CO2 laser cutting systems, which run particularly smooth. These systems cut smallest and finest structures without any problems, as well as material thicknesses of up to 40 mm. The edges are being polished at the same time, which makes subsequent reworking redundant.

From smallest technical components in mechanical and plant engineering to displays, logos, or signets in the advertising industry to covers and panes in automotive and aviation, the possibilities of thermoplastics are virtually endless.

Compared to traditional separation processes like sawing, drilling, and milling, thermal separating of Plexiglas® and Perspex® offers brilliant results while being significantly cost-efficient.

Should you have any queries regarding 2D laser cutting of acrylic glass (PMMA), Plexiglas®, and Perspex®, KURIOS’ engineers are happy to give you any advice you might need. Please get in touch with us.

Compared to traditional separation processes like sawing, drilling, and milling, thermal separating of Plexiglas® and Perspex® offers brilliant results while being significantly cost-efficient.

Should you have any queries regarding 2D laser cutting of acrylic glass (PMMA), Plexiglas®, and Perspex®, KURIOS’ engineers are happy to give you any advice you might need. Please get in touch with us.

Acrylic glass for many industries – everything from a single source

Advertising industry or display builder, as well as equipment in the field of medical technology, wind deflectors in automotive, or windows in the aviation industry – the range of applications is nearly infinite.

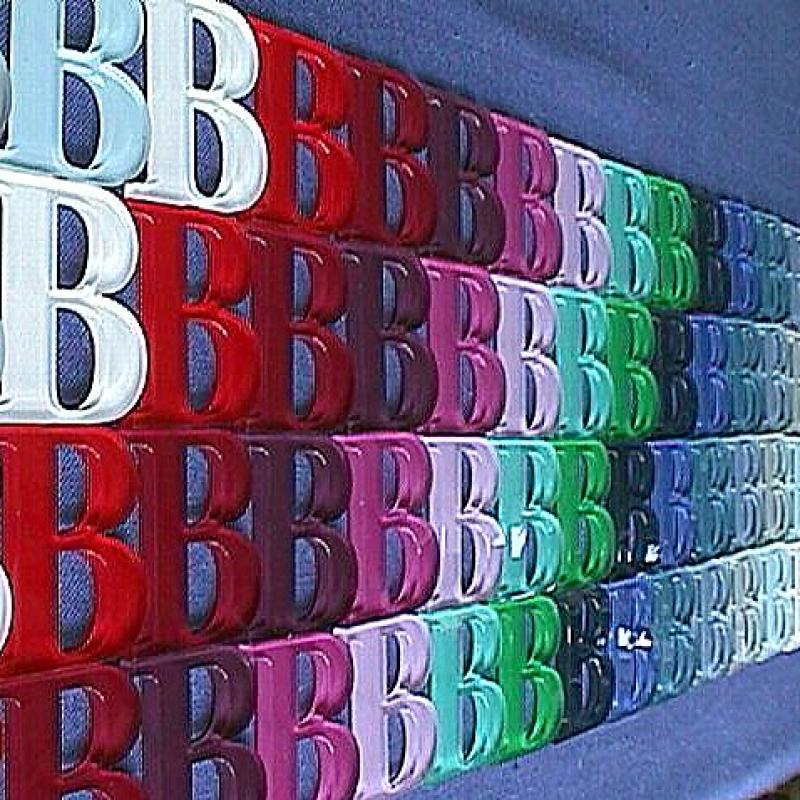

Letters in any color whatsoever

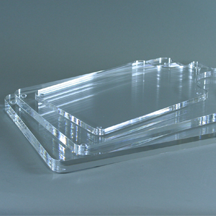

Money tray made of acrylic and toughened glass

Technical details for laser cutting acrylic glass

For 30 years, the founders of KURIOS have been dealing with the process of laser cutting non-metallic materials. As pioneers, our knowledge of handling thermoplastic synthetics has developed continuously over the last decades.

Meanwhile, besides laser technology, we have further options available to refine material cuttings and produce finished products. Engraving, turning, adhesive bonding, marking, sandblasting, milling and bending are just some of these options.

Through constant expansion and continuous further training of our staff, we have developed from a simple service provider in the field of laser cutting to a flexible manufacturer of finished products, who is looking forward to every new challenge.

Meanwhile, besides laser technology, we have further options available to refine material cuttings and produce finished products. Engraving, turning, adhesive bonding, marking, sandblasting, milling and bending are just some of these options.

Through constant expansion and continuous further training of our staff, we have developed from a simple service provider in the field of laser cutting to a flexible manufacturer of finished products, who is looking forward to every new challenge.

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum material thickness:

non-rigid materials from 0.05 mm

-

Maximum sheet thickness:

40 mm

-

Further processing offer:

Thermal bending, adhesive bonding, laser marking, engraving, turning, drilling, thread cutting, milling, and Heli-Coil

-

Surface treatment:

Sandblasting, abrasive blasting, grinding, brushing, lacquering, and further galvanic procedures

- Direct digital printing, screen printing, and pad printing