CNC Turning High-Performance Plastics

CNC Turning of PEEK, PTFE, or PPSU – precision turned parts from Seevetal near Hamburg

KURIOS Laserprodukt GmbH processes plastics in all variations. Besides engineering and advertising plastics, the use of high-performance plastics increases constantly. In many modern production facilities these high-temperature resistant and chemically stable materials fulfill tasks that other materials can hardly achieve, if at all.

It is very rare that classic clamping and machining parameters from metal-based jobs can be used for this group of plastics, which is why we need to consider every material’s unique characteristics. Relatively soft PTFE, for instance, requires that each clamping situation is thought through from scratch. Other plastics have abrasively acting additives, which complicates the selection of suitable machining tools or indexable inserts.

It is very rare that classic clamping and machining parameters from metal-based jobs can be used for this group of plastics, which is why we need to consider every material’s unique characteristics. Relatively soft PTFE, for instance, requires that each clamping situation is thought through from scratch. Other plastics have abrasively acting additives, which complicates the selection of suitable machining tools or indexable inserts.

Your product’s contours can be programmed offline by using latest CAD/CAM technology (e.g.: SolidWorks) or SIEMENS SinuTrain. Usually, most of the simple turning jobs are programmed directly at the machine by means of ShopTurn.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”. All production data is archived, so that any product is fully traceable and reproducible.

Our young and highly motivated team in the production area of machining is looking forward to your request regarding CNC turning of plastic. Feel free to contact us.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”. All production data is archived, so that any product is fully traceable and reproducible.

Our young and highly motivated team in the production area of machining is looking forward to your request regarding CNC turning of plastic. Feel free to contact us.

High-performance plastics are used in all industries

High-temperature range, mechanical engineering, medical technology, aviation, aerospace, chemical industry, electrical engineering, food industry, compressed air technology, nuclear industry

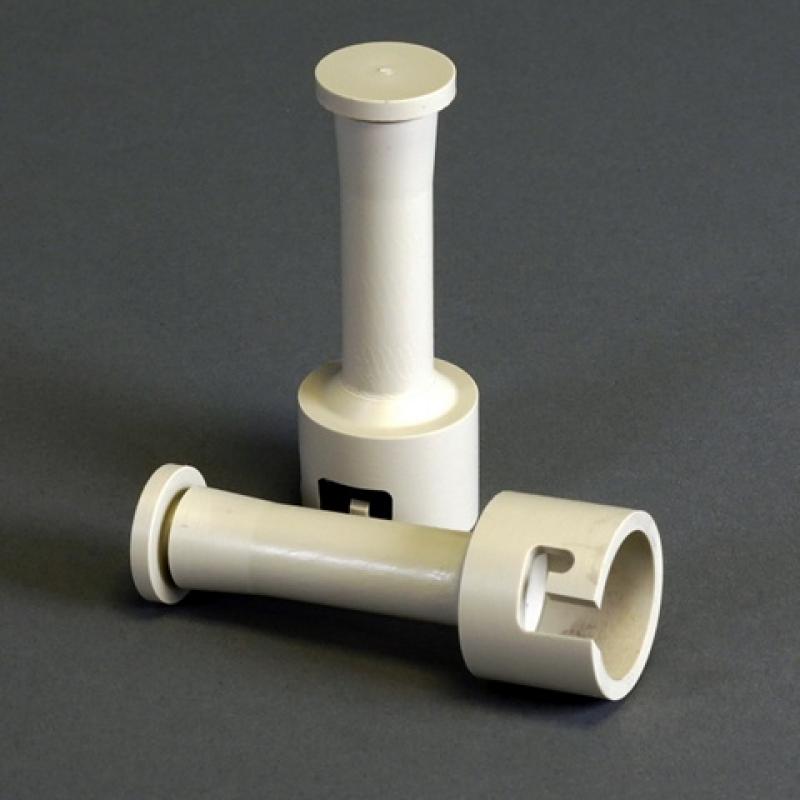

PEEK turned part

PTFE turned part

High-Performance Plastics

-

PEEK (Ketron®):

good mechanical properties, service temperature +240°C (+464°F), good stability at high temperatures, high radiation resistance

-

PAI (Torlon®)

maximum allowable service temperature at +250°C (482°F), good friction and wear behavior, high UV resistance

-

PPS (Techtron®)

very good mechanical properties, high permanent service temperature of +220°C (+428°F), good electrical insulation, excellent radiation resistance

-

PPSU, PSU, and PEI (Tecason®)

very good mechanical properties, good electrical insulation, approved to be used in food contact applications, suitable for steam sterilization

-

PTFE (Teflon®)

thermally stable from -220°C (-364°F) to +260°C (500°F), high chemical resistance, very low coefficient of friction, physiologically harmless

-

PVDF (Symalit®)

good antifrictional properties and wear resistance, good mechanical strength and rigidity, high toughness at low temperatures

CNC turning of high-performance plastic – technical details at a glance

CATIA, NX, and SolidWorks 3D data can be processed without any loss of quality in its native form. Furthermore, we are able to feed virtually all data exchange formats into our CAD systems. Even drawing-bound data poses no problem whatsoever.

-

Turning dimensions:

350 mm x 600 mm

-

Tools:

Twelve-fold turret with up to 12 driven tools, speed of up to 4,500 rpm, VDI40 holding fixture

-

Programming:

ShopTurn, SinuTrain, SolidWorks/HSMWorks

-

Further processing offer:

Laser cutting, welding, laser marking, HSC milling, 5-axis simultaneous milling, thermal bending, and adhesive bonding

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, and barrel finishing