CNC Turning Engineering Plastics

CNC turning of PE, PA, POM, etc. – everything from a single source

KURIOS Laserprodukt GmbH processes plastics in all variations. Expanding our range of services by adding a state-of-the-art CNC lathe enables us to respond even quicker to customer needs.

From simple plastic studs to highly complex components, we are constantly looking for solutions to meet the challenges each engineering plastic and its properties come with. For example, we need to start from scratch every time the clamping situation of a relatively soft plastic is thought through. Other plastics produce long chips that must be dealt with accordingly in order to ensure an unhindered machining process.

From simple plastic studs to highly complex components, we are constantly looking for solutions to meet the challenges each engineering plastic and its properties come with. For example, we need to start from scratch every time the clamping situation of a relatively soft plastic is thought through. Other plastics produce long chips that must be dealt with accordingly in order to ensure an unhindered machining process.

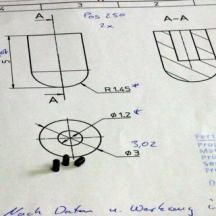

Your product’s contours can be programmed offline by using latest CAD/CAM technology (e.g.: SolidWorks) or SIEMENS SinuTrain. Usually, most of the simple turning jobs are programmed directly at the machine by means of ShopTurn.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”. All turning data is archived, so that any product is fully traceable and reproducible.

Our young and highly motivated team in Seevetal near Hamburg is looking forward to your request regarding CNC turning of plastic. Please contact us.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”. All turning data is archived, so that any product is fully traceable and reproducible.

Our young and highly motivated team in Seevetal near Hamburg is looking forward to your request regarding CNC turning of plastic. Please contact us.

Application fields of turned parts

Much like milled components, turned parts are required in every sector, for instance mechanical engineering, medical technology, food industry, plant engineering, chemical industry, electrical engineering, etc.

Turned PET bushing

Turned PA6 pulley

Engineering Plastics

-

PA (Ertalon®):

PA6, PA6.6, very good machinability, high strength, hardness and toughness, good electrical insulator, good antifrictional properties

-

POM (Ertacetal®)

excellent machinability, temperature resistant up to +110°C (+230°F), approved to be used in food contact applications, good antifrictional properties, dimensionally stable

-

PE (Murtfeldt®)

PE 300, PE 500, and PE 1000 with different grades of abrasion-resistance, approved to be used in food contact applications, low friction, high stiffness, chemical-resistant

-

PET (Ertalyte®)

high mechanical rigidity, low coefficient of sliding friction, very high wear resistance, approved to be used in food contact applications

-

Rigid PVC (Tecavinyl®)

high chemical resistance, high mechanical rigidity, stiffness, hardness, good electrical insulator

-

ABS (Tecaran®)

high mechanical rigidity and stiffness, easy to process, good scratch resistance and hardness, temperature-resistant up to +80°C (+176°C)

-

PC (Makrolon®)

very high impact strength, approved to be used in food contact applications, optimal light transmission, good machinability, high dimensional stability

-

PUR (polyurethane)

high elasticity, low temperature sensitivity, high tensile strength

-

LP, LF (laminated paper Pertinax®, laminated fabric)

very good mechanical properties, good electrical insulator, good machinability

-

GHM, GHGW (laminated glass mat, laminated glass fabric)

high mechanical rigidity, best electrical insulation, excellent high-voltage tracking resistance

CNC turning of engineering plastic – technical details at a glance

CATIA, NX, and SolidWorks 3D data can be processed without any loss of quality in its native form. Furthermore, we are able to feed virtually all data exchange formats into our CAD systems. Even drawing-bound data poses no problem whatsoever.

-

Turning dimensions:

350 mm x 600 mm

-

Tools:

Twelve-fold turret with up to 12 driven tools, speed of up to 4,500 rpm, VDI40 holding fixture

-

Programming:

ShopTurn, SinuTrain, SolidWorks/HSMWorks

-

Further processing offer:

Laser cutting, welding, laser marking, HSC milling, 5-axis simultaneous milling, thermal bending, and adhesive bonding

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, and barrel finishing