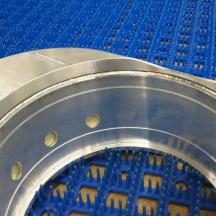

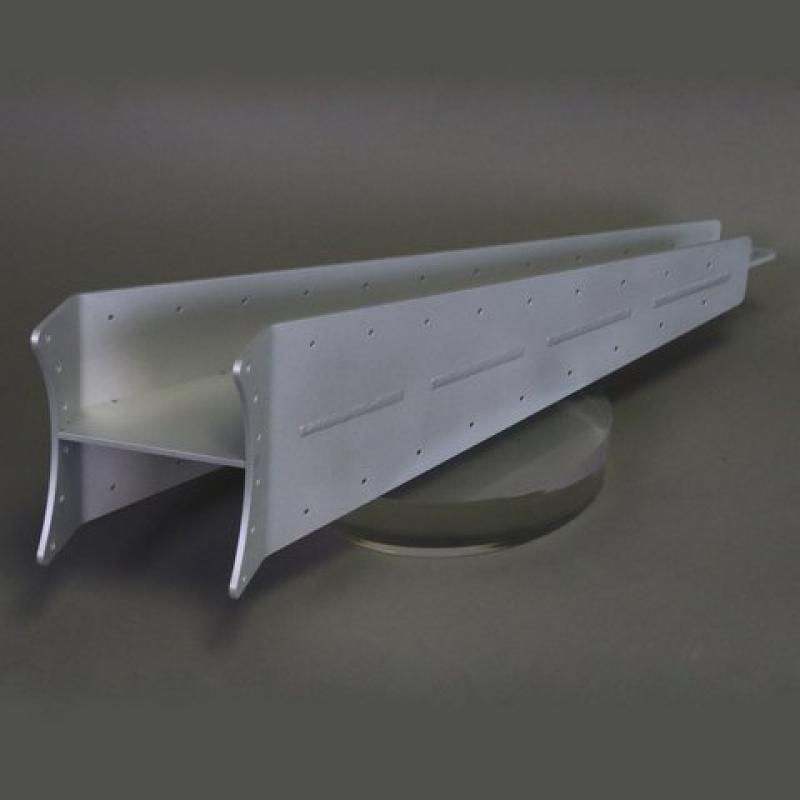

Laser Welding of Aluminium with or without filler material

Joint welding and repair welding

Short service routes and smooth communication provide the basis for superb welding results. Design, fixture construction, mechanical workshop, and welding department are together under a single roof at KURIOS, so that we are always able to react to requests as quickly as possible.

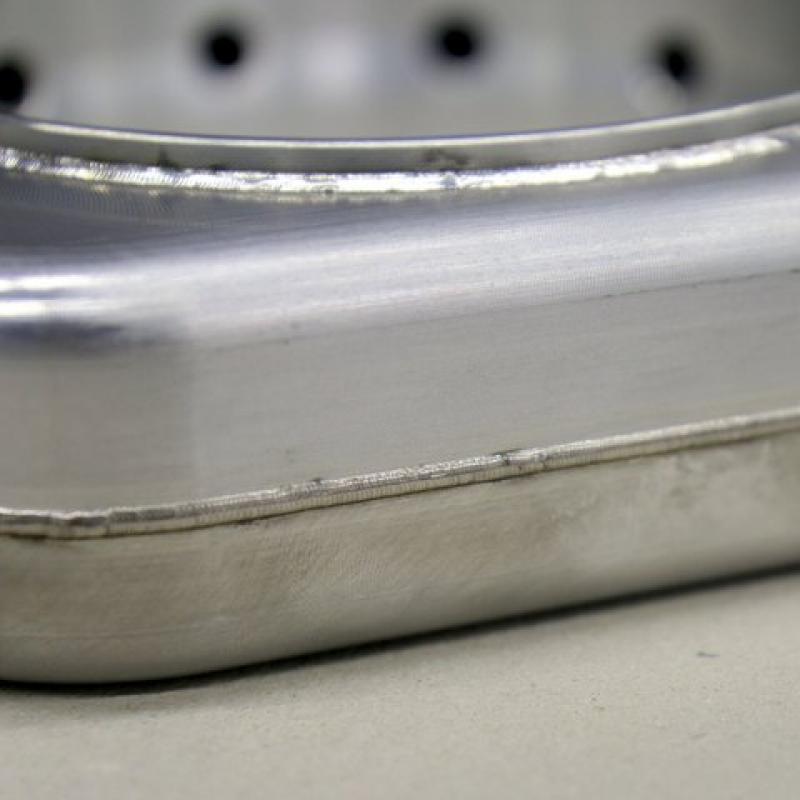

The main advantage pulsed laser welding has over other welding procedures is that the heat input is extremely low, which makes exceptionally tight geometric dimensioning and tolerancing feasible.

We have the technology and the necessary know-how. Benefit from that! We are looking forward to your request regarding laser welding. Please get in touch with us.

Laser fine welding of aluminium – possible fields of application

Laser welding of aluminium – the key facts at a glance

-

Maximum size:

1,000 mm x 1,000 mm

-

Minimum material thickness:

0.05 mm

-

Maximum material weight:

2,000 kg

-

Benefits:

Thermal effect that is lukewarm at most, high welding speed, various materials, no reworking, pinpoint energy exposure

-

With filler material:

AlMgSi 0.5, AlMgSi 1, AlMgSi 1.5, AlMgSi 2

-

Potentially weldable without filler material:

AlMg 3

-

Limited weldability:

AlMg 4.5

-

Further processing offer:

Laser cutting, HSC milling, bending, laser marking, engraving, thread cutting, drilling, turning, and thermal bending

-

Surface refinements:

Lacquering, sandblasting, abrasive blasting, grinding, and brushing