Laser Marking Acrylic Glass

Laser marking of advertising plastics and Plexiglas®

Acrylic glass (Plexiglas®, Perspex®) is diversely used in advertising, mechanical engineering, medical technology, and many other fields. Plexiglas® is weather-resistant, approved to be used in food contact applications, and perfect for visually appealing and functional components.

During the laser marking process, the CO2 laser removes a small part of the PMMA and roughens the surface. Regardless of material colors, a contrasty, abrasion-resistant laser marking emerges.

During the laser marking process, the CO2 laser removes a small part of the PMMA and roughens the surface. Regardless of material colors, a contrasty, abrasion-resistant laser marking emerges.

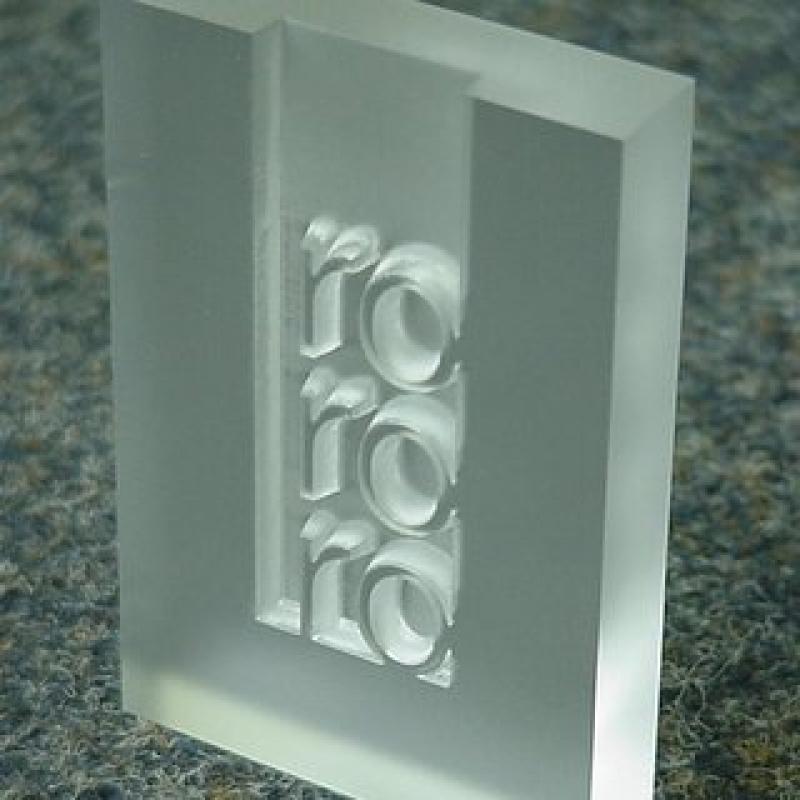

Besides decorative inscriptions, we have particular expertise in technical component markings, such as serial numbers, barcodes, QR codes, and data matrix codes. We are able to use our CO2 lasers for deep engraving, which results in particularly remarkable effects. Those topologies are achieved by the removal of more material.

So, if you are looking for a service provider to rely on at all times, you have come to the right place. We would be more than happy to receive your request.

So, if you are looking for a service provider to rely on at all times, you have come to the right place. We would be more than happy to receive your request.

Possible applications

Logos, signets, brandings, giveaways, awards – in the field of advertising practically everything is marked in a predominantly decorative way. For technical components the use of laser marking as identification by means of serial number, manufacturing date, and manufacturer’s signature prevails.

3D laser engraving of a flacon prototype

CO2 laser deep engraving

Laser marking of PMMA (Plexiglas®, Perspex®) – important details at a glance

Laser marking of acrylic glass is carried out by the use of CO2 lasers. Different designs of machines vary greatly in the material size they can process. Laser markers with scanner optics process extremely fast but come with editing field limitations of 200 mm x 200 mm. Flat-bed systems enable us to mark up to 2 m x 3 m large plates in just one go.

-

Maximum size of flat material:

2,000 mm x 3,000 mm

-

Minimum material thickness:

non-rigid material from 0.05 mm

-

Maximum size of workpiece:

1,000 mm x 500 mm x 500 mm

- File templates as vector file, bitmap, or image file from all common software products (*.ai, *.eps, *.dwg, *.dxf, *.bmp, *.jpg, etc.)

-

Further processing offer:

2D and 3D laser cutting, HSC milling, thread cutting, drilling, turning, and Heli-Coil

-

Surface refinements:

Lacquering, high-gloss polishing, sandblasting, abrasive blasting, grinding, and brushing

-

Further synthetic materials:

Engineering plastics, high-performance plastics, carbon