2D Laser Cutting GFRP/CFRP

Laser cutting of plastic composites (GFRP, CFRP, organic sheet)

Thermosetting or thermoplastic synthetic composites are extremely light while being rigid and strong, but require greater demands in terms of further processing. For cutting the contours of GFRP/CFRP component parts, we have a laser cutting technology at our disposal, which ensures consistent quality without any wear and tear.

Fiber-reinforced thermoplastics (organic sheets) are processed perfectly by the CO2 laser, as the thermoplastic material largely evaporates and no carburization occurs.

Fiber-reinforced thermoplastics (organic sheets) are processed perfectly by the CO2 laser, as the thermoplastic material largely evaporates and no carburization occurs.

Your components’ quality assurance takes place in-house throughout the entire production by the use of state-of-the-art FARO metrology and is constantly documented using a highly reliable ERP system named KISS. All laser cutting data is archived, so that we are able to reproduce any component and all requirements regarding traceability are met completely.

The KURIOS team is looking forward to your request. You can reach us via telephone or directly by means of the inquiry form.

The KURIOS team is looking forward to your request. You can reach us via telephone or directly by means of the inquiry form.

2D laser cutting GFRP/CFRP – possible fields of application

Light and strong – these characteristics are in great demanded among aircraft construction, racing, automobile manufacturing, shipbuilding, robotics, as well as innovative architectural engineering.

Glass fiber fabric laser cuttings

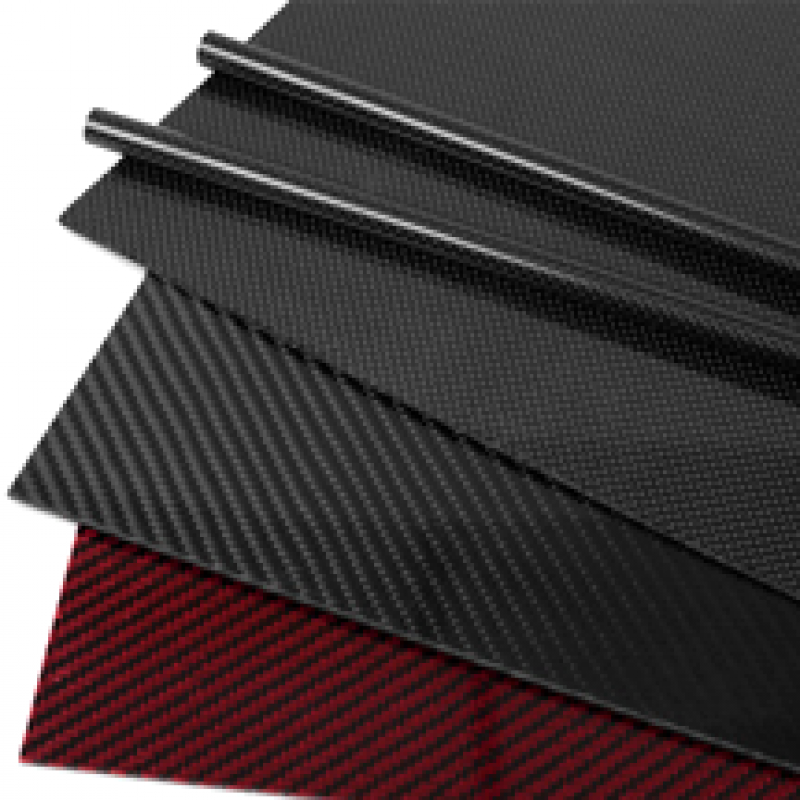

Semi-finished products made of carbon fiber

2D laser cutting GFRP/CFRP – all the relevant information

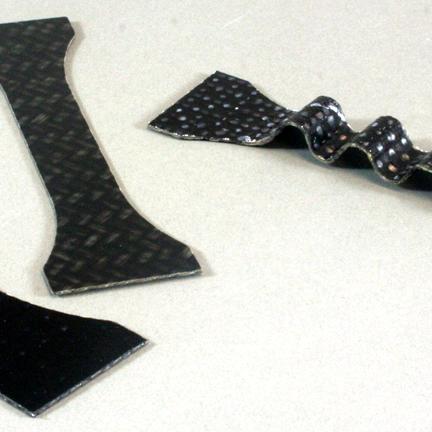

Due to our long-time expertise and technology, carbon and glass fiber-reinforced fabrics can be processed to the high-quality products. In addition, laser cut fabrics come with the benefit that edges easily melt, so that raw cuttings can be further processed in the lamination process. Completed semi-finished products made of reinforced synthetics are precisely laser cut and therefore make costly cutting dies unnecessary.

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum material thickness:

0.1 mm

-

Maximum sheet thickness:

5 mm

-

Further processing offer:

3D laser cutting, HSC milling, laser marking, engraving, turning, drilling, thread cutting, and adhesive bonding

-

Surface treatment:

Sandblasting, abrasive blasting, grinding, brushing, lacquering, and polishing