2D Laser Cutting Premium Steel

Thermal separation of VA, V2A, VA-foil, and stainless steel

Laser cutting of premium steel is a well-established method for quick, flexible, and economic industrial production. We specialized in cutting technologically sophisticated components, which can only be processed poorly or not at all by conventional laser cutting systems.

That’s why we specialized in handling non-rigid premium steel foil and visually pleasing design objects as well as all kinds of special materials and composites. We start processing materials from 0.01 mm thickness, which corresponds to a fraction of a piece of paper, and up to 3 mm thick premium steel sheets.

That’s why we specialized in handling non-rigid premium steel foil and visually pleasing design objects as well as all kinds of special materials and composites. We start processing materials from 0.01 mm thickness, which corresponds to a fraction of a piece of paper, and up to 3 mm thick premium steel sheets.

Premium steel letterings in combination with acrylic glass are very popular in the field of shopfitting and trade fair construction. Thanks to adhesive films, these high-gloss polished letters can be glued to the acrylic foundation. Since finish, optics and haptics play an important role, you get the combined processing of all materials from a single source.

Should you have any questions regarding 2D laser cutting of VA, V2A, VA foil, and stainless steel, do not hesitate to contact us. KURIOS’ specialists will be happy to assist you with advice and consultation.

Should you have any questions regarding 2D laser cutting of VA, V2A, VA foil, and stainless steel, do not hesitate to contact us. KURIOS’ specialists will be happy to assist you with advice and consultation.

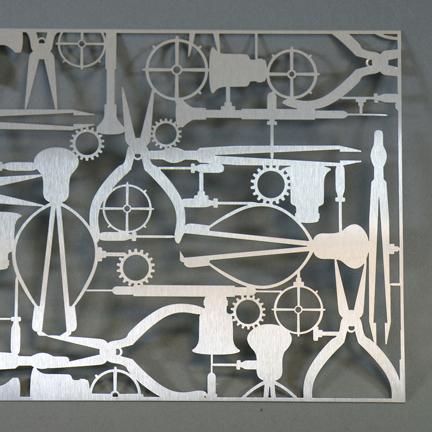

From spring steel foil to extraordinary design objects

Special materials, thin non-rigid foil, high-quality letters, signets, or components for Hi-Fi manufactories – KURIOS delivers unconventional work.

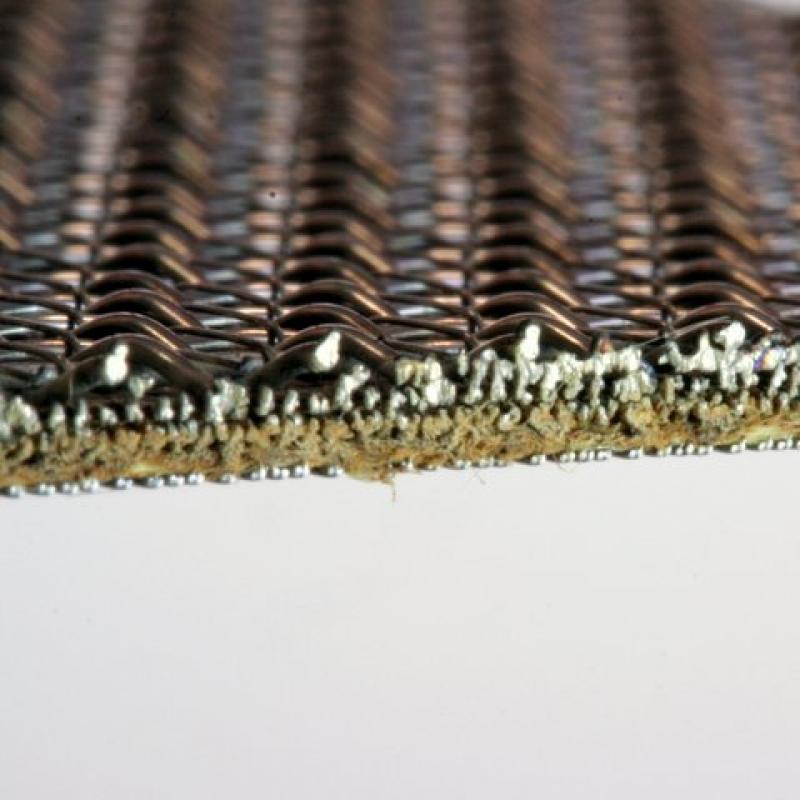

Premium steel meshed fire prevention mat

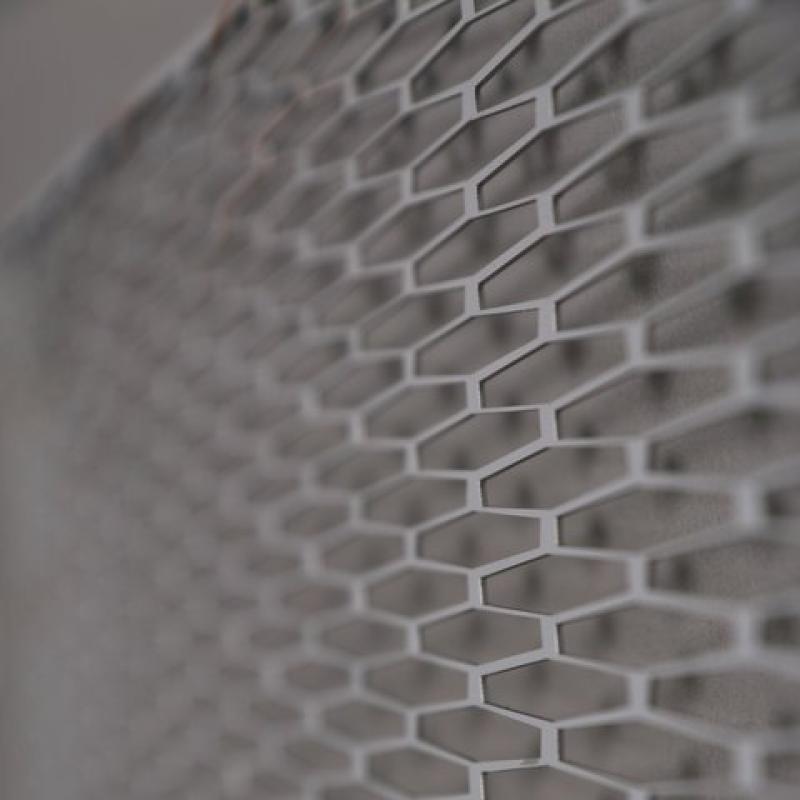

Speaker cover IIID surface

Technical details for premium steel laser cuts

Our production areas for metal manufacture true-to-dimension and ready-to-fit components with fine edges that don’t need to be reworked. Our laser cutting systems allow rectangular, burrless and oxide-free cutting of premium steel.

Due to our highly precise laser cutting systems and CNC milling machines, we are able to offer you optimal efficiency, which allows cost savings throughout the entire production chain from the very first draft to the finished product.

Due to our highly precise laser cutting systems and CNC milling machines, we are able to offer you optimal efficiency, which allows cost savings throughout the entire production chain from the very first draft to the finished product.

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum sheet / foil thickness:

non-rigid material from 0.01 mm

-

Maximum sheet thickness:

3 mm

-

Further processing offer:

Wire EDM, welding work, laser marking, engraving, thread cutting, drilling, turning, bending, milling and inserting studs

-

Surface treatment:

Sandblasting, satin finishing, grinding, brushing, polishing, barrel finishing, and further galvanic procedures