HSC Milling Acrylic Glass

High-speed machining of PMMA (polymethyl methacrylate), Plexiglas®, and Perspex®

Thanks to its physiological harmlessness and approval to be used in food contact applications, acrylic glass is not only used in advertising but also in medical technology, the laboratory environment, packaging industry, food environment, and even for windows in the field of aeronautical engineering.

To fully benefit from acrylic glasses outstanding properties, these applications require highest precision. For this purpose, we at KURIOS use high-end laser machines and powerful HSC milling systems.

To fully benefit from acrylic glasses outstanding properties, these applications require highest precision. For this purpose, we at KURIOS use high-end laser machines and powerful HSC milling systems.

Surely, we are able to process native data of CATIA, NX, or SolidWorks as well as use virtually all data exchange formats. By using CAD/CAM systems our entire machinery can be programmed offline, which results in us being able to trace or reproduce all production-relevant data.

Quality assurance is continuously happening while we process your components. All the recorded data is stored in our ERP system “KISS”.

If you are looking for a service provider you can absolutely rely on, we would be happy to receive you request.

Quality assurance is continuously happening while we process your components. All the recorded data is stored in our ERP system “KISS”.

If you are looking for a service provider you can absolutely rely on, we would be happy to receive you request.

Acrylic glass – an ingenious material with endless possibilities

Observation windows in submarines that dive into the deepest trenches of our oceans or even the Starfighter’s cockpit windows – acrylic glass is to be found 10,000 m above and 10,000 m below mean sea level.

Inside view of a marine diesel engine’s crankcase through 20 mm thick acrylic glass

Frosted 60 mm block material with engraving

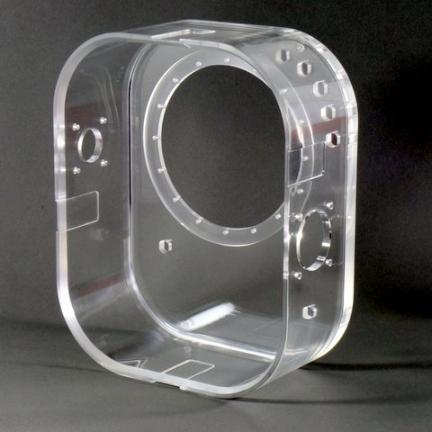

HSC milling of acrylic glass (PMMA: polymethyl methacrylate) – important details summarized

Due to the material’s glass-like brittleness, acrylic glass is only machinable with special tools. Rake angle, clearance angle, and wedge angle differ immensely from the ones used to process other plastics or metal. If one takes these factors into account and uses rigid, high-quality milling systems with powerful and smoothly running spindles, outstanding results can be achieved.

Besides the option of manual polishing, a final finishing pass with diamond-tipped tools is necessary to receive a polished surface.

Besides the option of manual polishing, a final finishing pass with diamond-tipped tools is necessary to receive a polished surface.

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum material thickness:

0.1 mm

-

Maximum material thickness:

200 mm

-

Machines:

Flatbed milling machines, portal milling systems, 5-axis milling machines

-

Industries:

Shopfitting, trade fair construction, advertising, illuminated signage, glazing, food industry, medical technology, aviation

-

Further processing offer:

2D and 3D laser cutting, 5-axis simultaneous milling, laser marking, turning, hydraulic bending, and Heli-Coil

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, and polishing