3D Volume Models

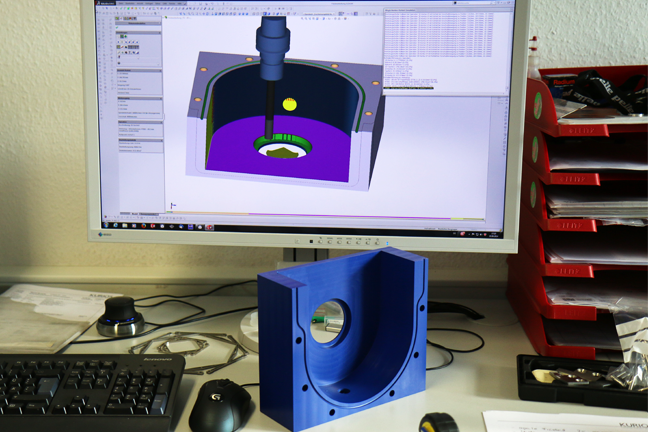

SolidWorks® as our CAD solution, HSMWorks® as our CAM solution

Besides Inventor® and a few other products, SolidWorks® has developed into an industrial standard in the field of parametric designing with volume models.

Many CAM solutions build on the solid foundations of that CAD base. The most efficient CAD/CAM systems however, are fully integrated under one surface. That makes precise and efficient processing possible without having the downside of detours.

Extensive importing possibilities enable us to read and process virtually all data exchange formats of other CAD products.

All post-processor modifications for our laser, milling, and EDM machines are done at KURIOS. That way, we are in control of the entire process chain and are able to react quickly to new requirements.

Many CAM solutions build on the solid foundations of that CAD base. The most efficient CAD/CAM systems however, are fully integrated under one surface. That makes precise and efficient processing possible without having the downside of detours.

Extensive importing possibilities enable us to read and process virtually all data exchange formats of other CAD products.

All post-processor modifications for our laser, milling, and EDM machines are done at KURIOS. That way, we are in control of the entire process chain and are able to react quickly to new requirements.

Investing in modern CAD/CAM technology and intensively training our staff to successfully utilize it is the key to make sure that our customers will receive superb quality at all times. That can be assured by consistently having in-house training and external courses. KURIOS’ experts are always up to date.

Today, we are not only able to program our machines offline but also do designs. We now are capable of conducting analyses, such as a collision analysis, kinematic analysis, and FEM analysis. We can also give our customers a perfect idea of how their product is going to look like by using 3D animations and photorealistically rendered images.

Today, we are not only able to program our machines offline but also do designs. We now are capable of conducting analyses, such as a collision analysis, kinematic analysis, and FEM analysis. We can also give our customers a perfect idea of how their product is going to look like by using 3D animations and photorealistically rendered images.