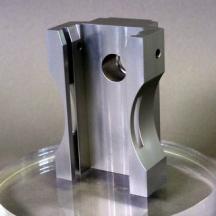

HSC Milling Aluminium

High-speed machining of aluminium and other non-ferrous metals

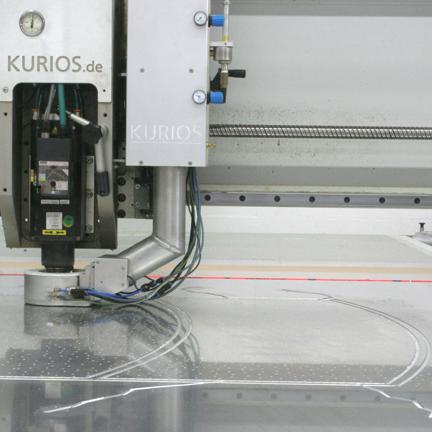

Working with latest, rigid milling machines enables us to process aluminium in its optimal process window, which ensures quality and shortest possible processing time. Here we make use of dry machining processes or minimum quantity lubrication systems.

When dealing with your constructions, our long-term experience helps us to manufacture even more cost-efficient by optimizing production steps.

You may submit your request over the phone or directly by using our inquiry form.

Aluminium and its varied alloys are used in all fields

HSC milling of aluminium – relevant information summarized

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum material thickness:

0.5 mm

-

Maximum material thickness:

100 mm

-

Machines:

Flatbed milling machines, portal milling systems

-

Further processing offer:

2D and 3D laser cutting, 5-axis simultaneous milling, laser marking, CNC turning, hydraulic bending, and Heli-Coil

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, and polishing

-

Range of materials:

Rolled aluminium sheets, aluminium cast plates, aluminium extrusion profiles, copper, brass, and bronze