METEK – precise measurements in any weather

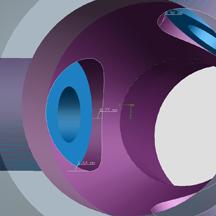

Laser welding of premium steel

Arctic winter. The thermometer drops to -50°C (-58°F) and icy winds are blowing with up to 250 km/h (155 mph) across a bizarre landscape of ice and snow. Men as well as technology are exposed to extreme conditions inside Antarctica’s weather stations. But whether it is in perpetual ice or burning deserts, on the Zugspitze or at the Irish coast, measuring instruments are required everywhere. They need to deliver most precise data at all times regarding the direction and speed of wind (ultrasonic anemometer). Plenty of human lives rely heavily on the anemometer’s reliability.

KURIOS welds individual components together by means of laser welding methods. There is a demand for these instruments in all kinds of fields where safety has the highest priority, such as seafaring, aviation, and mining, and KURIOS makes sure that the respective data can be trusted. Let us give you an example: during take-off and landing, the pilot is in need of weather data that is exact to the second in order to make air traffic as safe as possible. When approaching the remotest airfields in the most chaotic weather situations, every pilot expects reliable information. Sudden freezing rain, blizzards, hurricanes, or torrential rain describe “normal operating conditions” and are not allowed to affect the data in any way.

KURIOS welds individual components together by means of laser welding methods. There is a demand for these instruments in all kinds of fields where safety has the highest priority, such as seafaring, aviation, and mining, and KURIOS makes sure that the respective data can be trusted. Let us give you an example: during take-off and landing, the pilot is in need of weather data that is exact to the second in order to make air traffic as safe as possible. When approaching the remotest airfields in the most chaotic weather situations, every pilot expects reliable information. Sudden freezing rain, blizzards, hurricanes, or torrential rain describe “normal operating conditions” and are not allowed to affect the data in any way.

The company METEK Meteorologische Messtechnik GmbH is specialized in extreme conditions.

As a reliable partner of the Elmshorn-based (near Hamburg) company, KURIOS welds all premium steel components for their ultrasonic anemometers. Due to experienced project management and close cooperation, we were able to develop an optimal manufacturing process. The construction of precision instruments has been made suitable for laser welding and conventional soldering and bonding methods have been replaced.

The great advantage: that solution makes it possible to weld even already wired subsystems without any functional loss. As a consequence, we were able to optimize some stages of production and enhance product requirements, particularly with regard to durability and tightness.

That way, METEK’s ultrasonic anemometers will withstand the coming Arctic winters without a doubt.

As a reliable partner of the Elmshorn-based (near Hamburg) company, KURIOS welds all premium steel components for their ultrasonic anemometers. Due to experienced project management and close cooperation, we were able to develop an optimal manufacturing process. The construction of precision instruments has been made suitable for laser welding and conventional soldering and bonding methods have been replaced.

The great advantage: that solution makes it possible to weld even already wired subsystems without any functional loss. As a consequence, we were able to optimize some stages of production and enhance product requirements, particularly with regard to durability and tightness.

That way, METEK’s ultrasonic anemometers will withstand the coming Arctic winters without a doubt.

You are looking for someone in the field of material processing and you want to be able to fully rely on your service provider while you feel in good hands? Please feel free to get in touch with us. We will be pleased to receive your request!