Surface Refinements

Surface treatment for plastics, metals, and natural materials

Our refinements lead to perfect surfaces, from corundum blasting and glass bead blasting to lacquering. Whether you are looking for surfaces that are nobly matte but glossy, colorfully painted, or textured, KURIOS takes care of your product’s appearance.

The majority of surface refinements are carried out in-house, regardless of whether we are dealing with metal, plastic, or natural material. We are particularly proud of our industrial paint booth and AkzoNobel Sikkens color mixing system. These enable us to do professional paint jobs in all RAL colors, spot colors, or special lacquers ourselves.

Galvanic procedures (burnishing, chromating, and phosphating), powder coating, or anodizing procedures are done in cooperation with carefully selected partners.

The majority of surface refinements are carried out in-house, regardless of whether we are dealing with metal, plastic, or natural material. We are particularly proud of our industrial paint booth and AkzoNobel Sikkens color mixing system. These enable us to do professional paint jobs in all RAL colors, spot colors, or special lacquers ourselves.

Galvanic procedures (burnishing, chromating, and phosphating), powder coating, or anodizing procedures are done in cooperation with carefully selected partners.

Polishing, abrasive blasting, or satin finishing of metal gives these products the final gloss and can also be used to remove burrs.

Plastics, especially acrylic glass, are often polished after the machining process is finished to restore the original gloss and high transparency.

Grinding and abrasive blasting procedures are applied to treat the surfaces of wood and other natural materials, so that a perfect finish can be achieved.

Our highly motivated team is looking forward to your requests. Please get in touch with us.

Plastics, especially acrylic glass, are often polished after the machining process is finished to restore the original gloss and high transparency.

Grinding and abrasive blasting procedures are applied to treat the surfaces of wood and other natural materials, so that a perfect finish can be achieved.

Our highly motivated team is looking forward to your requests. Please get in touch with us.

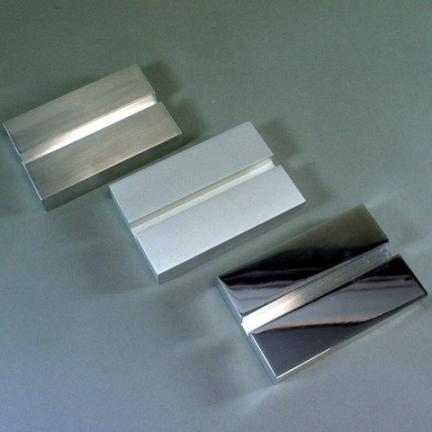

Exemplary applications – glass bead blasting of premium steel

Glass bead blasting is the perfect choice to process premium steel and aluminium. It makes it possible to establish semi-glossy, non-reflecting, visually homogeneous (design) surfaces on aluminium. Furthermore, the use of these techniques removes impurities, such as welding slag. Glass bead blasting is an essential surface finish for medical devices.

Aluminium, hard coated

200 mm acrylic glass, polished

Surface refinements – technical details at a glance

-

Corundum blasting:

Compressed air blasting procedure with sharp-edged corundum grains; surface roughness is determined through grain size, pressure, and exposure time; outstandingly suitable for derusting and paint stripping purposes

-

Glass bead blasting:

Compressed air blasting procedure with glass beads; surface roughness is determined through grain size, pressure, and exposure time; the material surface is slightly condensed and leveled, which makes it insensitive to contamination

-

Satin finishing, brushing:

Surface finish for premium steel; applying a brush stroke with grinding tools of 240 grit or finer

- Siebdruck oder alternativ Tampondruck lassen sich auf unterschiedlichsten Bauteilgeometrien anwenden - Vorgaben nach Luftfahrt- und Bahnnormen oder MIL lassen sich umsetzen.

-

Polishing:

Metal polishing results in a perfectly reflecting surface; aluminium, steel, premium steel, copper, brass, and noble metals are extremely suitable. Plastic polishing is mainly used with acrylic glass and results is highly transparent and glossy surfaces

-

Barrel finishing:

Deburring method with a shaking barrel and grinding tools; time of exposure, shake frequency, and the geometry of grinding tools determine the deburring result

-

Galvanic procedures:

Nickel plating, galvanizing, chromating, decorative anodizing (natural, black, colored), hard coating (technical anodizing, natural, black, colored)

- Pulverbeschichten: glänzend, seidenmatt oder strukturiert - vollflächig oder partiell abgedeckt - auch in Kombination mit galvanischer Vorbehandlung