CNC-Controlled Hydraulic Bending

Bending of various metals as well as plastics (PC, PETG)

Hydraulic bending with CNC-controlled press brakes is one of the standard applications in sheet metal processing. We are able to bend all conventional metals up to a thickness of 10 mm thanks to our multidirectional sheet metal bender. Special tools enable us to cover a broad range of bending radii (1 mm to 20 mm). In some cases those required tools are manufactured at KURIOS. Furthermore, we engaged ourselves in cold bending of plastics, so that we can offer you to bend a variety of thermoplastics. These require that we take specific characteristics into account like the completely unconventional springback. Due to the consistent documentation of all relevant data in our ERP system “KISS”, we are able to draw on that precious knowledge base at any time.

We find a solution to any bending matter. Our wide-ranging production offers many different opportunities, which encourages lateral thinking and new solutions.

Our entire team ensures optimized and smooth operations from consultancy and programming with latest CAD/CAM technology to the optimal result and its delivery.

If you want to be able to unconditionally rely on your service provider and feel in good hands at all times, KURIOS is the right place to be. At KURIOS you will get unlimited flexibility from a single source. Get in touch with us.

Our entire team ensures optimized and smooth operations from consultancy and programming with latest CAD/CAM technology to the optimal result and its delivery.

If you want to be able to unconditionally rely on your service provider and feel in good hands at all times, KURIOS is the right place to be. At KURIOS you will get unlimited flexibility from a single source. Get in touch with us.

Bending sheet material – an important refinement

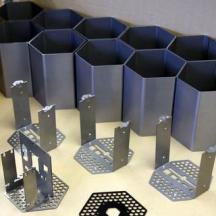

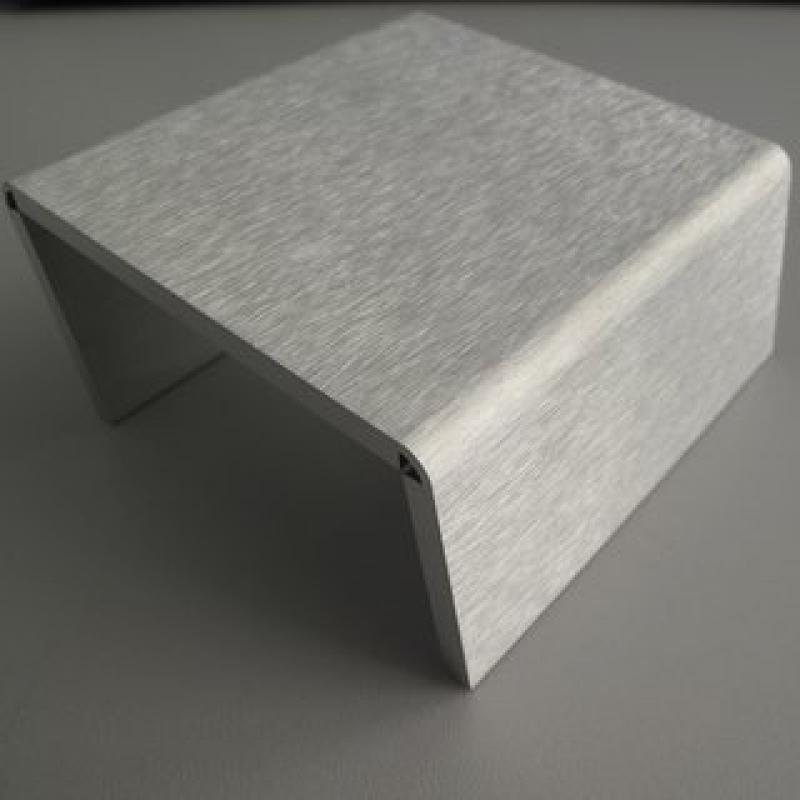

Usually, laser-cut and milled components made of plane material are not finished after the cutting process is done since further work is necessary, including bending. We process the full range of metallic and non-metallic materials, which is how we gathered a lot of expertise in handling sensitive materials. These materials require us to minimize any marks of processing.

8 mm aluminium ground, relief-milled, and bent

1 mm premium steel sheet, bent

Some important facts about hydraulic bending

The CNC leaf brake is programmed directly at the machine’s Delem 66 control. The correction factors of the respective material and its thickness are recorded not only here but also inside our CAD software SolidWorks, which ensures smooth and quick operations.

-

Bending width:

1,200 mm

-

Material thickness:

from 0.1 mm to 10 mm

- Designed with SolidWorks and programmed with Delem 66

-

Metal:

Steel, premium steel, aluminium, copper, brass, titanium

-

Plastic:

Polycarbonate (PC), polyethylene terephthalate glycol (PETG)

-

Further preparatory work:

3D laser cutting, 3D milling, laser marking, inserting studs, thread cutting, finishing