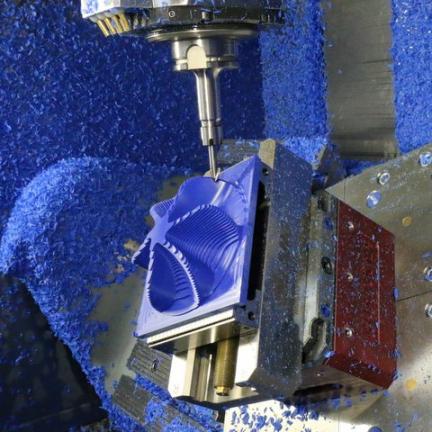

5-Axis Milling Engineering Plastics

Milling of PA (polyamide), PE (polyethylene), and POM (polyoxymethylene)

By using latest 5-axis milling systems, we are able to offer very efficient, double-sided processing. Furthermore, these systems enable us to produce any freeform surface whatsoever, so that even more constructive possibilities are feasible.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”.

So, if you are looking for a service provider you can rely on at any time, we would be more than happy to process your request.

Engineering plastics substitute even metals

Engineering Plastics

-

PA (Ertalon®):

PA6, PA6.6, very good machinability, high strength, hardness and toughness, good electrical insulator, good antifrictional properties

-

POM (Ertacetal®)

excellent machinability, temperature resistant up to +110°C (+230°F), approved to be used in food contact applications, good antifrictional properties, dimensionally stable

-

PE (Murtfeldt®)

PE 300, PE 500, and PE 1000 with different grades of abrasion-resistance, approved to be used in food contact applications, low friction, high stiffness, chemical-resistant

-

PET (Ertalyte®)

high mechanical rigidity, low coefficient of sliding friction, very high wear resistance, approved to be used in food contact applications

-

Rigid PVC (Tecavinyl®)

high chemical resistance, high mechanical rigidity, stiffness, hardness, good electrical insulator

-

ABS (Tecaran®)

high mechanical rigidity and stiffness, easy to process, good scratch resistance and hardness, temperature-resistant up to +80°C (+176°C)

-

PC (Makrolon®)

very high impact strength, approved to be used in food contact applications, optimal light transmission, good machinability, high dimensional stability

-

PUR (polyurethane)

high elasticity, low temperature sensitivity, high tensile strength

-

LP, LF (laminated paper Pertinax®, laminated fabric)

very good mechanical properties, good electrical insulator, good machinability

-

GHM, GHGW (laminated glass mat, laminated glass fabric)

high mechanical rigidity, best electrical insulation, excellent high-voltage tracking resistance

5-axis milling of engineering plastics – some details

Data preparation is a fully three-dimensional process. CATIA, NX, or SolidWorks data can be processed in its native form. Additionally, we are capable of feeding virtually all data exchange formats into our CAD systems. Complete offline programming of all orders by means of our CAD/CAM systems ensures that all relevant data traceable at any time.

-

Maximum size:

850 mm x 700 mm x 500 mm

-

Minimum material thickness:

0.05 mm

-

Machine:

Hermle C400

-

Further processing offer:

Large format milling, 2D and 3D laser cutting, welding, thermal bending, laser marking, hydraulic bending, and turning

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, brushing, and further galvanic procedures