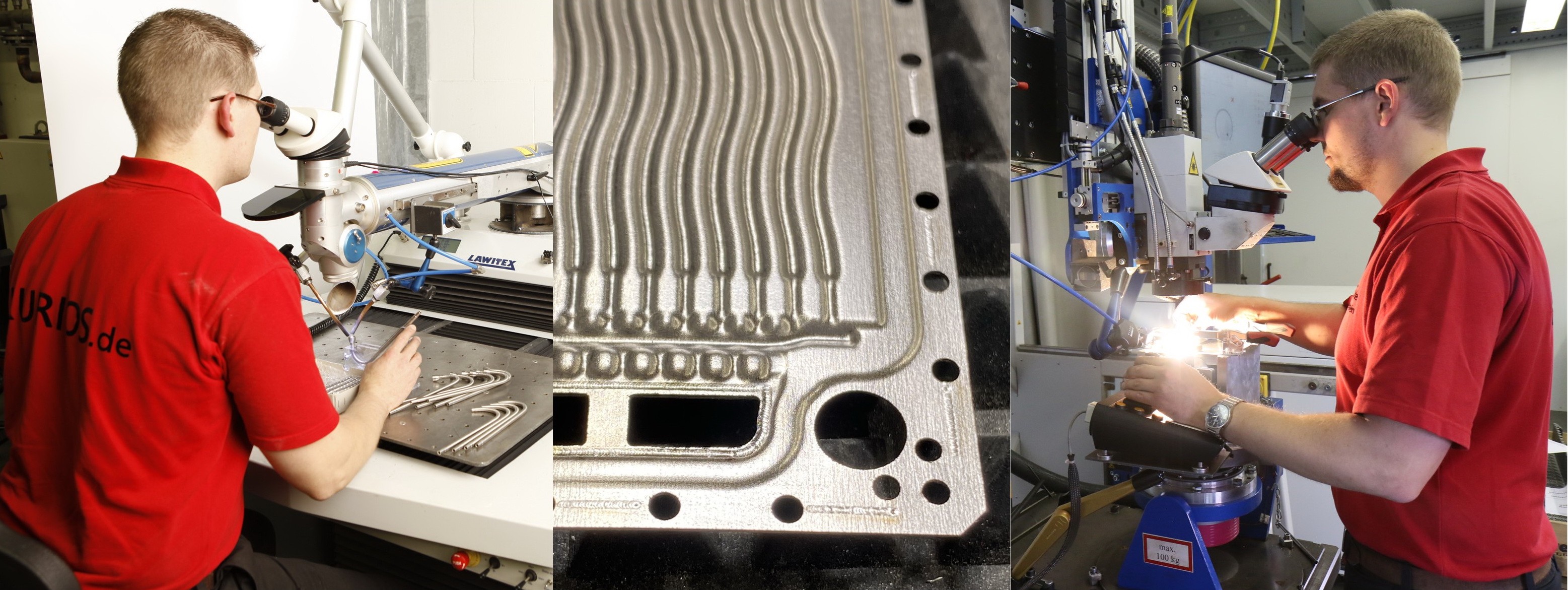

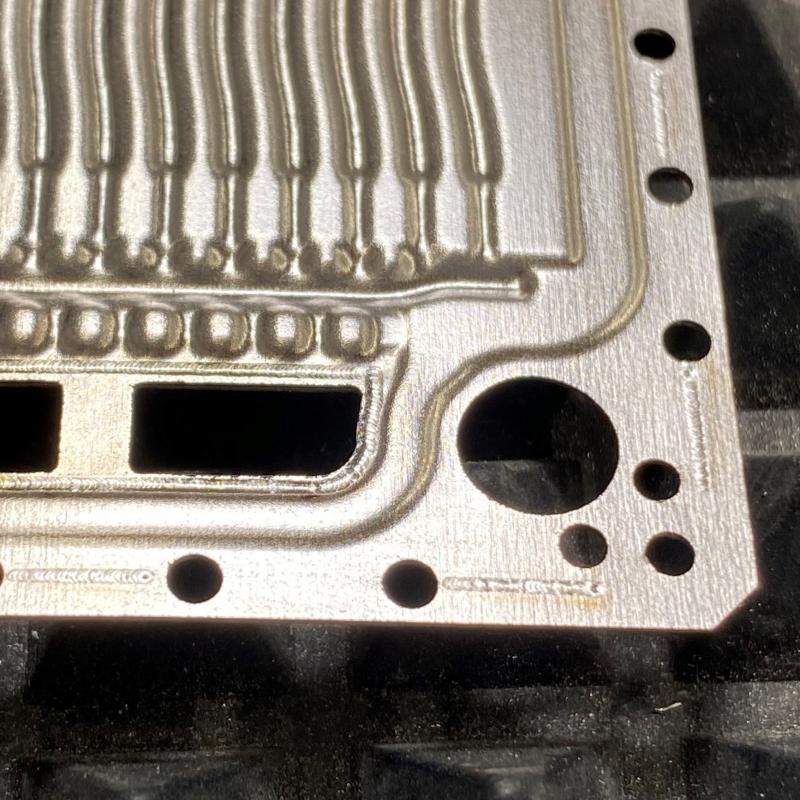

HSC milling, sheet metal working, laser welding are competences of KURIOS

5-axis milling of engineering plastics, laser welding of aluminium with filler material, decorative electroplating and flawless surfaces - we can do a lot and now a lot more.

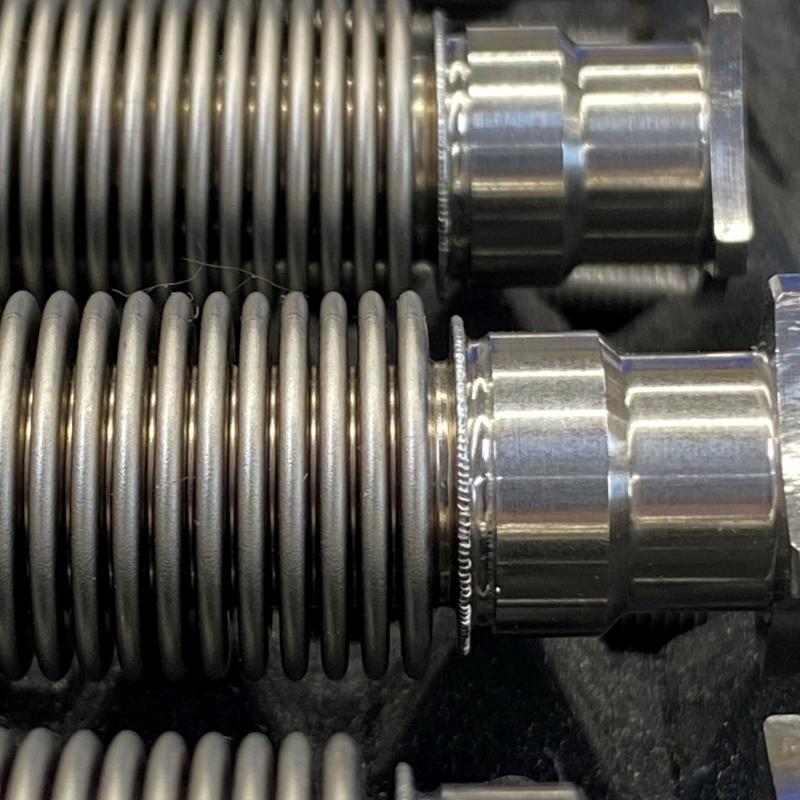

Since its foundation in 1994, KURIOS Laserprodukt GmbH has been active as a service provider in the field of metallic and non-metallic manufacturing with state-of-the-art manufacturing technologies in the areas of laser fine welding, laser cutting and laser marking as well as machining with the areas of HSC milling, large-format milling, 3- and 5-axis machining and turning centres. In addition to contract manufacturing for our customers in the medical technology, railway technology, mechanical engineering and electrical engineering sectors, we also develop and produce our own products under the DailyCustoms and DailyKnives brand names.

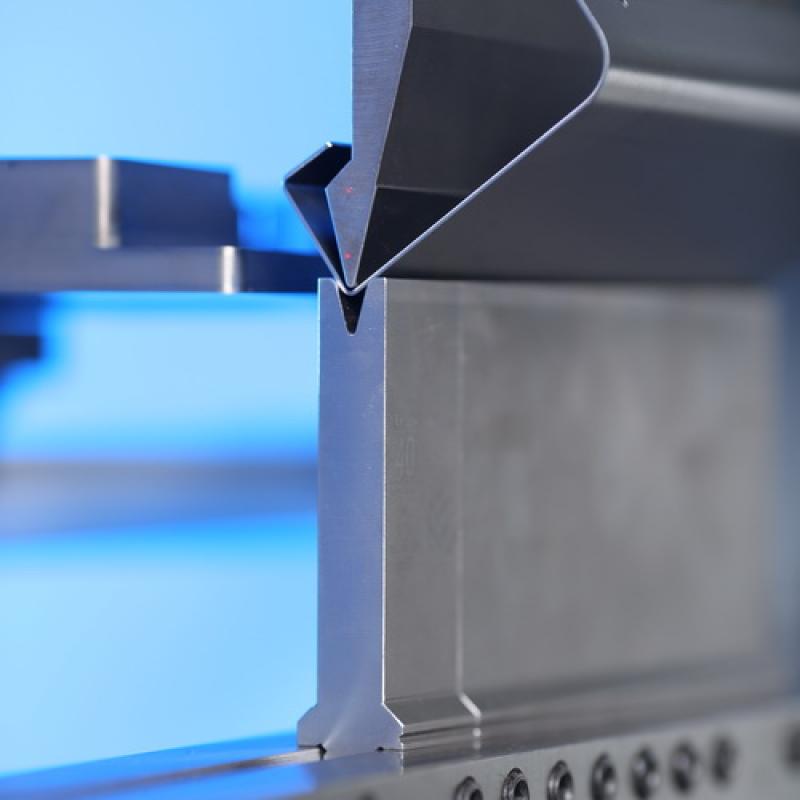

- Laser welding

- Laser marking

- Laser cutting

- Laser cleaning

- HSC milling

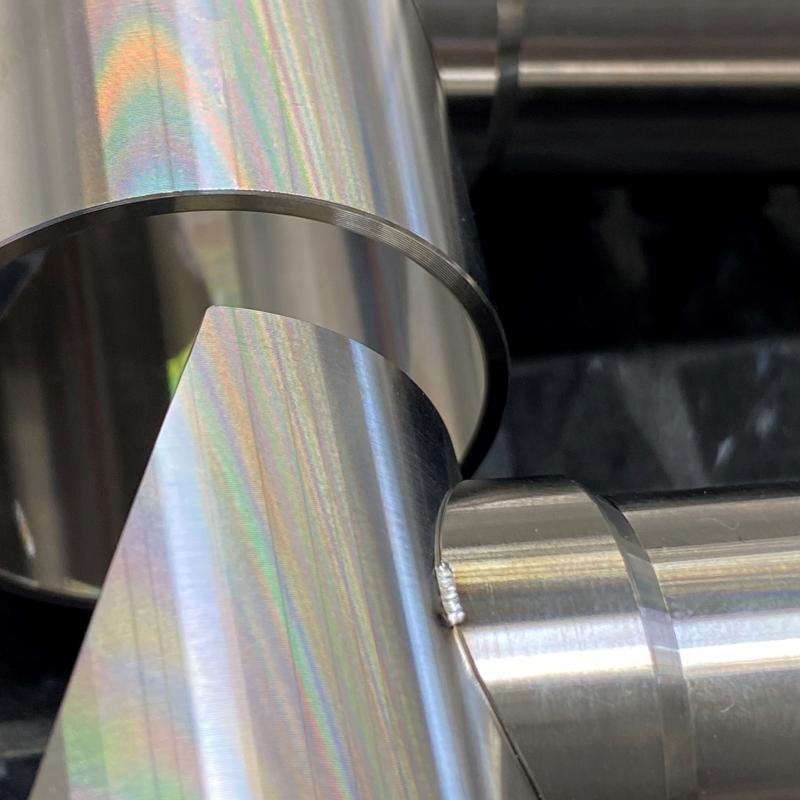

- 5-axis milling

- 3-axis milling

- Panel milling

KURIOS - Competence that pays off

Hydraulic bending of optically demanding sheet metal assemblies, long belt grinding of stainless steel and aluminium components, glass bead blasting of medical components, rapid prototyping with filament and resin printers, customised product development, production optimisation and consulting for welded assemblies, design and development of EDC products, sheet steel powder-coated as light displays with LED technology, brochure stands, backlight foil displays, large-format laser inscription up to 2mx3m, logos and lettering made of MDF, acrylic glass or stainless steel sheet, laser cuts made of carbon fibre fabric, glass fibre fabric or Kevlar, product labelling with DataMatrix code, high-quality stainless steel assemblies for small animal cages, gas-tight laser welding on aluminium suspension strut assemblies, welding on electromechanical or electronic components

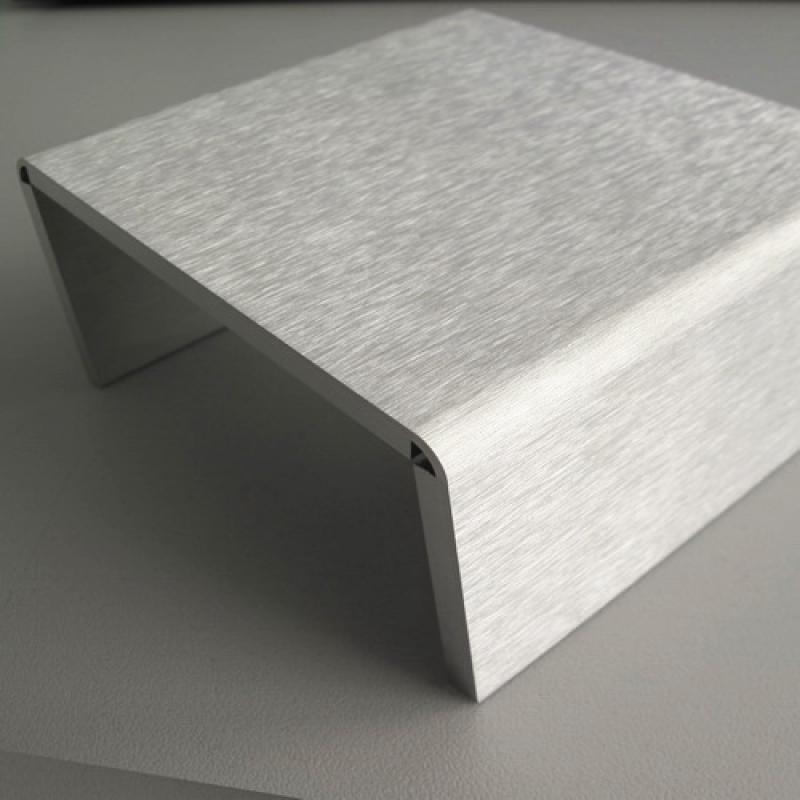

Laser welding of surgical cutlery, laser welding with filler material of aluminium housings, laser welding of laser components, laser welds laser, HSC milling of composite materials, heavy-duty machining of tool steels, large-format aluminium plate machining, highly transparent 2D and 3D plastic components, perfectly ground stainless steel housings, precise laser cutting in acrylic glass with screen printing, milling systems with camera system for the detection of register marks, anodised aluminium enclosures, pad printing on front panels, hard anodising on aluminium components, partial powder coating of demanding enclosures, front panels with sub-anodised printing as screen printing or digital direct printing, laser inscription with colour change for titanium components, deep engraving with the laser with 3D effect, laser cutting of brushed stainless steel sheet, laser fine welding of stainless steel enclosures.